4 Great Ways to Insulate Wires Without Electrical Tape

Wiring tape. Simple product, right? Well, it might be. When the electrical tape is appropriately applied, it can be a valuable asset for lots of different jobs like insulating motor lead connections. Having an alternative to electrical tape can also save you some significant frustrations. You may have the electrical tape, but getting another item handy around the house or garage tends to be necessary.

Electrical tape is an excellent choice for your last bullet, but there are other safe ways to insulate wires without it. Alternatives for electrical tape are as follows: wire nuts, friction tape, and heat shrink tubing.

Electrical tape is a solid product, and it’s excellent for insulation. But what if you don’t have it? Many substitutes can get the job done. This blog post will discuss insulating wires without electrical tape by using other household items like wire nuts.

Under no circumstances should you attempt repairs on live wires — disconnect freestanding devices or verify the breaker is off for home repairs before working on electrical items.

What is Electrical Tape?

Electrical tape is an inexpensive general-purpose insulating tape with excellent resistance to moisture, abrasion, and corrosion. You can use the tape to insulate electrical wires and other materials that conduct electricity and minor repairs to damaged cables. Most manufacturers make electrical tape from vinyl due to its elongation properties.

Electric tape protects wires and cords from outside elements like dust and moisture that may cause damage over time. Most users appreciate electric tape for its fire retardancy, electrical insulation, resistance to voltage, alkali, acid, and cold. Insulation tape is available in a broad range of sizes and lengths for different applications.

You can use the tape for professional and domestic purposes like joining wires and cables, automobiles harnesses, packaging, color code indicator, electrical applications, paint masking, and color-coding.

4 Ways to Insulate Wires Without Electrical Tape

There are several ways to insulate wires without electrical tape. Let’s see other products used for insulation.

1. Heat- Shrink Tubing

Heat shrink tubing, also known as heat shrink, is a shrinkable tube that shrinks when exposed to heat. It looks tubing looks a bit like straw or hollow plastic coffee stirrer, depending on its thickness. The plastic tube surrounds two wires before being heated to solder and hold them together. Manufacturers use polyolefin materials to make heat shrink tubing. The materials can withstand high temperatures up to 125°C–135°C.

Manufacturers can also use PVC-based material to produce heat shrink tubing. PVC- based materials cannot withstand higher temperatures like polyolefin materials. Typically PVC-based materials have a maximum temperature of 105°C. However, PVC is more affordable than polyolefin. PVC-based heat shrink tubes provide brighter and more vibrant colors. They also offer better clarity if you need a transparent box. PVC is also available in flammable retardant genres and has greater tensile strength and abrasion resistance than polyolefin materials.

Heat shrink tubing is also accessible in other materials such as FEP, PTFE, PVDF, elastomeric, silicone rubber, Viton, and other specialty materials. The use of these materials depends on the environment of the shrink tube. Heat shrink tubing protects your wires from abrasion, scuffing, cutting, and low-impact situations. You can use it with any design of conductor.

Different companies use heat shrink tubing to create cable entry seals protecting the surrounding environment. When using the heat shrink tubing, it’s important to twist the bare wire ends and solder them together, then slide the tubing over the wire connection. A heating mechanism such as a heat gun shrinks the tubing tightly over the link, preventing the wires from falling apart. Heat-shrink tubing often is used on small wires in electronic devices, but you can also use it in household wiring systems. The shrink tubing binds wires together; it is a viable substitute for a cable jacket.

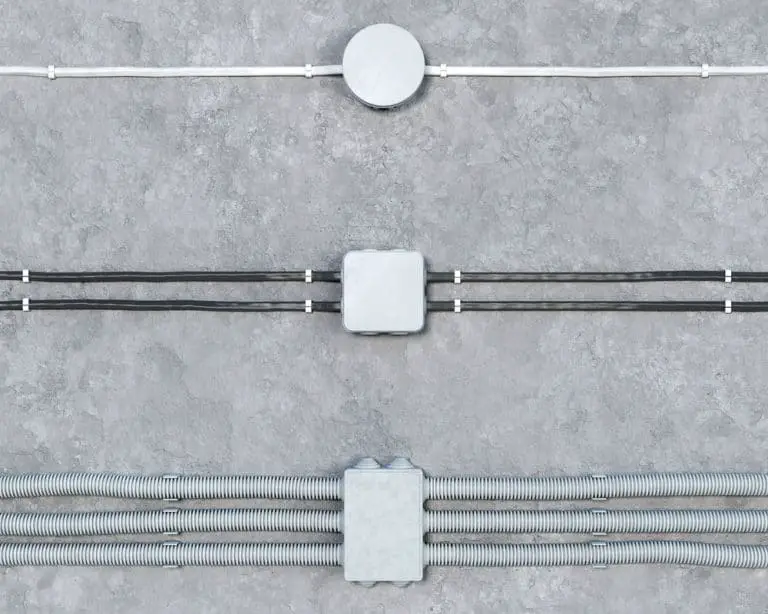

2. Wire Nuts

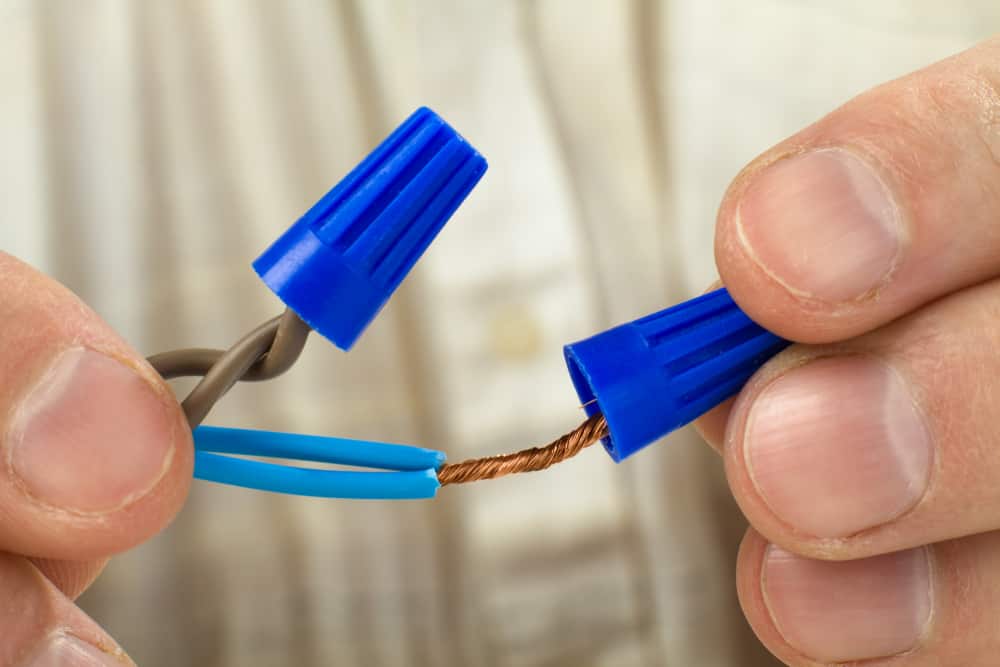

They are also known as wire connectors or wire caps. Wire connectors are elementary devices used to create connections between two or more electrical wires or terminations. Wire nuts have long been the primary devices for joining circuit wires in house wiring systems, while twisting wires together and covering the connection with electrical tape is no longer accepted by most building codes. They allow for an electrical connection without soldering.

The parts of a wire nut include the insulator, which can vary in material depending on application requirements such as nylon, plastisol, rubber, etc. A brass insert is crimped into the end of insulation to secure it onto the screw terminal, the wire entry part where wires enter from the top side, and the wings with teeth at the bottom are used for gripping bare conductors when installing into device terminals.

Wire nuts look like small plastic sacks with metal inside them (the “teeth”). When you twist together stripped ends of your wires, slide the wire nut over them, and then screw it tight. Nuts twist onto the bare ends of wires to guarantee a secure, insulated, yet reversible connection.

Wire nuts come in different colors; you can choose your wire nut color according to the specific conductor needs of the wires you connect. You can use wire nuts to connect both stranded and solid core wires for power distribution, control circuits, and low voltage data circuits in house wiring systems. They provide a safe connection that does not require stripping of insulation from conductors or terminal screws.

3. Friction Tapes

Friction tape was the first electrical tape to infiltrate the marketplace. Manufacturers make it with cloth or fiberglass with an adhesive coating on one side. Friction tapes are flame-retardant, hence used for wrapping wires, hoses, and other items.

The tapes offer good protection against abrasion, mechanical damage due to moisture, weathering, chemicals, and solvents. The major drawback of these tapes is the lack of tensile strength at elevated temperatures, limiting their use in applications where continuous exposure to high temperature occurs like electric motors, etc. They provide insulation from short circuits but are not good insulators over long periods under normal conditions.

Some users mainly use them for electrical wire splices, heavy-duty binding, household wiring, bundling cables, and adding no-slip grip to construction and agricultural equipment handles. You can apply friction tape like rubber tape; however, it does not stretch. When using friction tape, extend the tape over onto the insulation at the other end of the splice, then rewind a second layer along with the splice until you get to the original starting point. Cut the tape and firmly press down the ends to complete the job. The standard color of friction tape is black, but you can get more colors.

4. Duct tape

Despite its multiple functions, duct tape can fix electrical wires but not for long. Now there are different types of duct tape;

- Adhesive aluminum foil. Adhensive aluminum foil is not common today because aluminum is a conductive metallic material.

- Polyethene/Plastic. The duct tape in the market today comes in cloth fabric with polythene on both sides. Fabric and plastics are non-conductors of electricity. There is a wide range of polythene/fabric duct tapes with different end uses. Examples are; the general-purpose duct tape that works well enough for odd jobs where long service life isn’t necessary. Industrial grade tapes are more of a workhorse because of their added adhesive coating weight. True-duct tape withstands prolonged heat but is mainly used to seal air ducts.

The polythene duct tape is a slightly non-conductive material; hence safe to wrap exposed wires temporarily. The fabric mesh is slightly burnable, but since manufacturers coat it with plastic, it renders the fabric non-flammable. Before using duct tape to insulate wires, consider the voltage that flows inside live electrical wires. One wrap of electrical tape can protect against 600 volts because that is its purpose. Even multiple wraps of duct tape can’t warrant that kind of protection. That’s not the duct tape’s job!

Duct tape can insulate wires BUT for LONG because it uses cloth fibers in its backing. When the cloth fiber touches electrically charged wires, it can dry out over time and possibly even conflagrate; especially, when they carry high voltages of electricity. In addition, duct tapes are not long-lasting. If you cover electrical wiring connections using these tapes, in due course, they will wear out.

Duct tapes are not UL tested, neither are they UL certified. Meaning, professionals did not manufacture nor sanction them for electrical use. If you don’t have electrical tape and require to insulate a wire instantly, you can use duct tape. But once you get the electrical tape, you have to replace it with the electrical tape.

Unsafe Substitutes of electric tape

There are a few unsafe alternatives commonly used in do-it-yourself projects. They include;

Foil Tape

Foil tapes have aluminum foil as the base material instead of cloth or fiberglass backing like friction tape. The major problem with using aluminum foil is that, unlike other materials, aluminum will conduct electricity when pressed against the bare wire. It’s best to use foil tape when you are hoping to achieve airtightness and moisture resistance. You can use foil tape in several applications thanks to its versatility and durability, but not as an alternative to electric tape.

Scotch Tape

Scotch is another alternative that most people have in their homes. Although they have an adhesive backing, manufacturers did not design them for electrical wiring purposes. The tapes do not have electrical insulation properties.

Scotch tape is not conductive but lacks dielectric properties, especially over a shattered globe, to be considered safe. To be safe, don’t use scotch tape to insulate electrical wire connections. You can use it for other designs like package sealing, art projects, etc

Masking Tape

Masking tape is another popular alternative that you can use, but it’s not safe. A masking tape does not consider design parameters such as electrical insulation properties or others required for safe and effective use for most electrical services. However, masking tapes are not highly flammable due to their high heat resistance.

A silicon-based adhesive masking tape might be used in temperatures up to 500°C, though it can still catch fire at some point. It may take a bit longer than the typical paper (due to the water content in the adhesive), but once the glue dries, it will catch fire without a problem. For safety purposes, you should only use UL-listed electrical tape to connect anything that conducts electricity.

Different Types of Electric Tapes

There are many types of electrical tapes sold on today’s market, with a wide variety of intended uses, key attributes, materials, colors, and sizes on offer. As with most such products, the best kind to use will entirely depend on the scenario and the job you expect it to perform. The most popular varieties are;

- PVC Insulation Electrical Tape comes with excellent resistance to abrasion, water, and chemicals, so it’s very durable. The biggest drawback of this electrical tape is that you cannot use it at high temperatures because the plasticizers are combustible under these conditions.

- Vinyl Electrical Insulation Tape- You can use it on general wiring, insulation, and repair jobs. It gives solid performance against abrasion, moisture, chemicals, and changeable temperatures. Often, you can find it in low-voltage household and workplace electrical applications for repairs and insulation.

- Silicone Rubber Insulation Tape has excellent chemical resistance properties and outstanding adhesive qualities, making this type entirely suitable for high-temperature applications. It’s not resistant to abrasion, water, or chemicals, so you must use it with caution.

- PTFE Electrical Insulation Tape is the best of all tapes because it’s resistant to solvents, acids, and bases. It can also be used in high-temperature and low temperatures applications, making this type very versatile for different uses.

- Mastic Electrical Insulation Tape is the type of tape typically found in household and commercial environments. It has a high level of chemical resistance, low levels of friction, good abrasion resistance qualities, and excellent water-proofing properties, making this particular kind perfect for numerous applications at home or office use.

The Benefits of Using Electrical Tape to Insulate Wires

Electrical tapes may appear just like any other tape, but they have very distinct and significant benefits that make them unique. The benefits include:

- They prevent possible electrocution. The electrical tape comes as a non-conductive material. If you are using it to insulate your wires, the chance of getting electrocuted is meager. It saves you from shock and other accidents.

- Insulate Electrical Wires. The primary purpose of electrical tape is to insulate wires. It will protect your circuits from getting exposed when repaired or installed in a different location.

- They prevent possible fire hazards. In some cases, you can use electrical tape to insulate wires carrying high voltages of electricity. There will be no chance of fire or overheating when you do the correct insulation, preventing possible explosions and significant accidents.

- They are easy to work with. Electrical tape is straightforward to use. It is very flexible, and you can cut it in any way that fits your needs. You don’t need unique tools or skills to work with it!

- They are reusable. After using the tapes to insulate your wires, you can easily remove them and use them again in the future.

- They are very durable. The electrical tape is made to work in extreme conditions. It will last for a long time, and it is resistant to damage by sunlight, water, or chemicals.

- They are readily available. You can find electrical tapes anywhere; they are sold at hardware stores and online for a price that anyone can afford.

Conclusion

Before starting an electrical repair, it is crucial to make sure you use suitable tape for the job. Many types of tape are sold on today’s market, with a wide variety of intended uses, key attributes, materials, colors, and sizes on offer. As with most such products, the best kind to use will entirely depend on the scenario and the job you expect it to perform. However, electrical tapes are the best to use when insulating your wires.